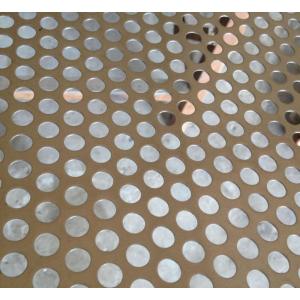

Perforated filter made of perforated sheet, can be classified into

perforated cylinder filter, perforated basket filter, perforated

cone filter and perforated tube filter. Generally it is made of

stainless steel, carbon steel, aluminum or copper sheet and the

hole shape is round or square. With accurate filtration rate,

perforated filter can filter a large variety of fluids and retain

almost any size solids. With high mechanical strength, perforated

filter is mainly used in petroleum, chemical industry, pharmacy,

food making filtration and sewage water filtration, etc.

Specifications

Material: stainless steel, carbon steel, aluminum, copper,

galvanized steel sheet, etc.

Sheet thickness: 3 gauge - 36 gauge.

Layers: single layer or multiple layers.

Edge processing: with wrapping edge or metal flange.

Perforated hole patterns: round, square, slot, etc.

Filter precision: 2-2000 µm.

Features

High porosity and excellent permeability.

Corrosion resistance and high temperature resistance.

Accurate filtration precision.

Easy processing and installing.

Easy forming, painting, polishing, welding and cleaning.

Firm structure and different hole patterns.

Applications

Perforated metal filter is widely used in petroleum, chemistry,

metallurgy, machine, medicine, automobile industries for

distillation, absorption, evaporation and filtration processes, so

as to eliminate the impurity and foam mixed in the gas and liquid.

Filtration of air: air filters, vacuum filters, filtration of

corrosive gases, cage ventilation, etc.

Filtration of liquid: ceramics polluted water cleaning, beverage,

disposal of sewage water, filtration of corrosive liquids, beer

brewing filter, etc.

Filtration of solid: glass, coal, food processing industry,

cosmetics, fluidised beds, etc.

Filtration of oil: oil refining, hydraulic oil, oilfield pipelines,

etc.

Filtration of other fields: textile industry, insulation industry,

automotive industry, chemical industry, metallurgy, pharmacy,

electronic field, etc.